3D Inspection

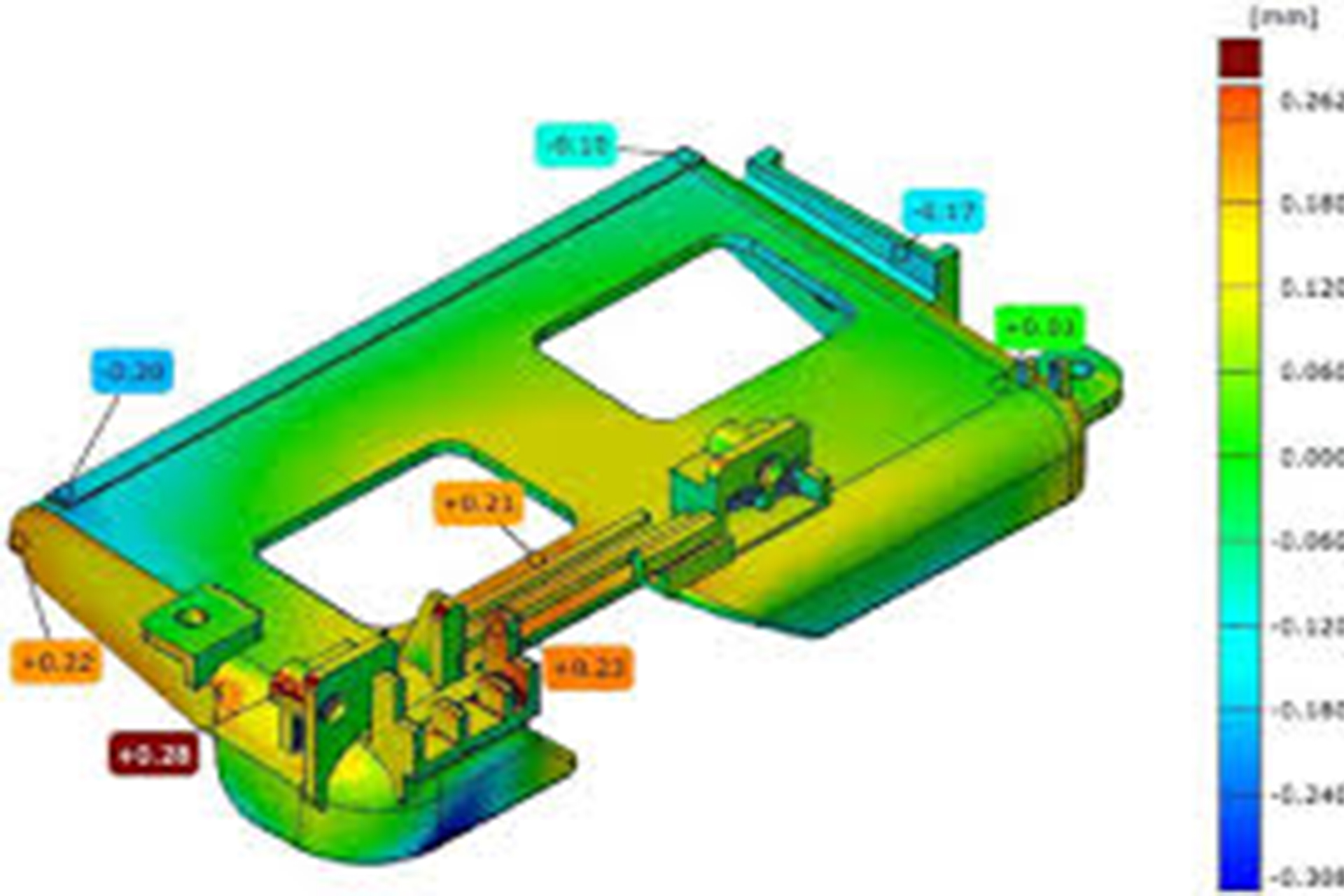

Ensure unmatched accuracy and quality with Zeno 3D’s advanced 3D Inspection Solutions. Using cutting-edge blue light and laser scanning technologies, our team captures highly precise 3D measurements of your components, from the simplest parts to the most complex geometries. With accuracy up to ±0.01 mm, we ensure that every critical dimension is analyzed thoroughly. Our process provides deep insights into deviations, surface imperfections, and assembly fit, empowering manufacturers to maintain the highest standards of precision and reliability in their products.

Core Features of 3D Inspection

Why Choose Zeno 3D for 3D Inspection?

Ultra-Precise Measurements

Every critical component is measured with extreme precision, down to ±0.01 mm. Our meticulous scanning process ensures that even microscopic deviations are detected, enabling manufacturers to produce parts that fit perfectly in assemblies, maintain performance standards, and reduce waste.

Detailed Deviation Analysis

We provide a full CAD vs part comparison, along with GD&T reporting, highlighting any deviations from specifications. This allows engineers to quickly identify areas requiring adjustment, ensure regulatory compliance, and improve overall product quality.

Fast Reporting

Inspection results are delivered rapidly, typically within 48 hours. Fast reporting allows design and production teams to take immediate corrective actions, reduce downtime, and meet tight project timelines without compromising on accuracy.

Trusted Across Industries

Our 3D inspection services are relied upon by leaders in automotive, aerospace, medical, and industrial manufacturing sectors worldwide. Zeno 3D ensures consistent quality and performance, making us a trusted partner for companies requiring high-precision inspection services.

3D Inspection

Ensuring Precision & Quality

At Zeno 3D, our 3D Inspection services provide a comprehensive end-to-end solution for verifying, validating, and improving component dimensions and quality. By leveraging advanced 3D scanning technologies, we capture every detail of physical parts and generate highly accurate digital models. These models allow precise CAD comparisons, detailed GD&T reporting, and informed decision-making for quality control processes.

Our inspection services are ideal for automotive, aerospace, industrial, and medical applications. Companies can ensure strict compliance with industry standards, reduce manufacturing errors, and optimize production efficiency. Detailed deviation reports provide engineers and designers with actionable insights, enabling proactive adjustments and continuous product improvement.

Zeno 3D also provides seamless integration with prototyping, production, and reverse engineering workflows. This ensures that inspection results are immediately actionable, helping teams identify potential issues early, save costs, and streamline the overall product development cycle. With our services, manufacturers can confidently deliver high-quality products that meet exact specifications and exceed customer expectations.